Quality Consistent

Consistency in quality is at the core of Hengjiu. From raw materials to finished products, every step adheres to ISO quality management standards.

Since the establishment of the factory, there has never been a case of bulk returns. We have been an inspection-free supplier for well-known European brands for many years.

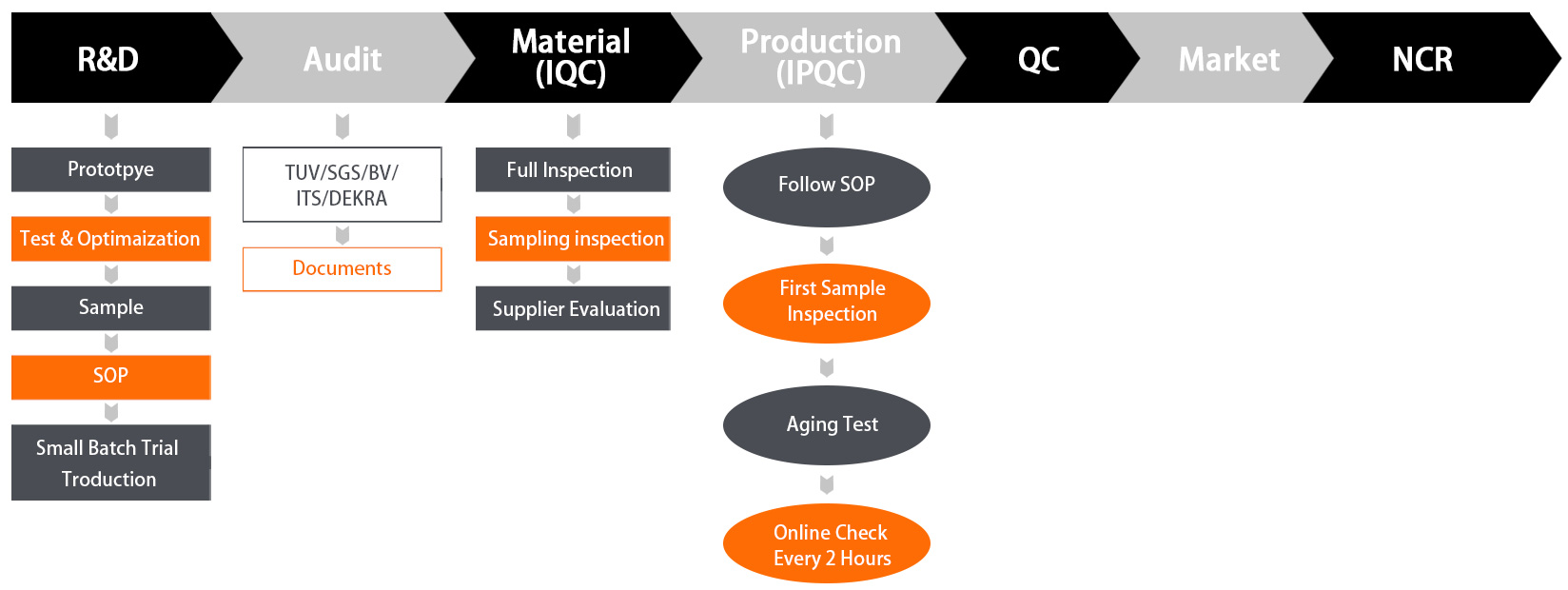

At Hengjiu, ensuring the consistent quality of our products is achieved through a comprehensive quality management system comprised of the following seven key stages:

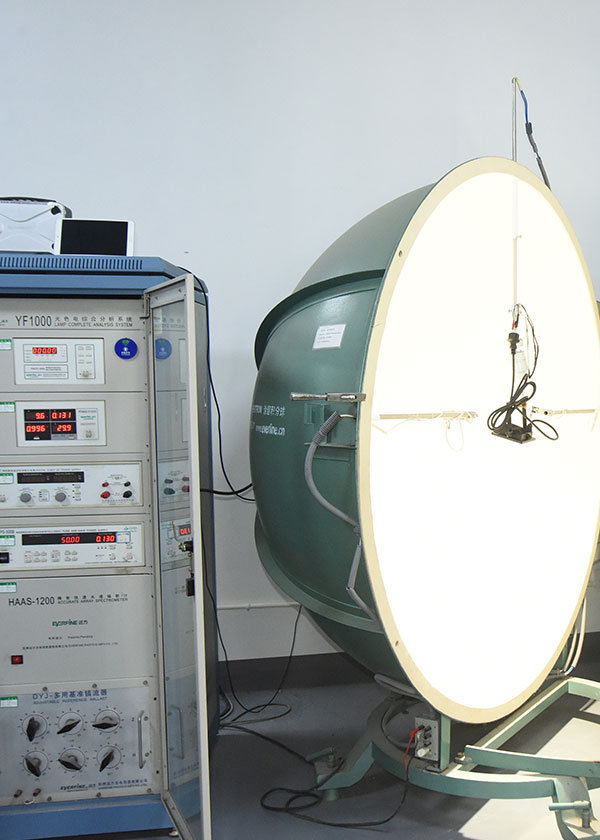

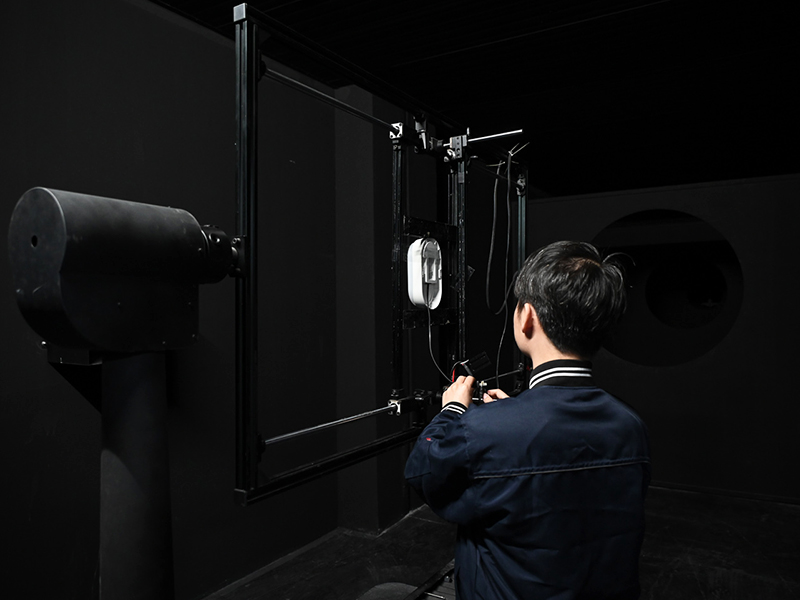

Third-party testing agency

Before mass production, we will send the products to third-party organizations, such as TUV, BV, SGS, ITS, DERAK, to apply for certifications including GS, CE, EMC, ERP, RoHS, REACH, CB, and SAA.

This process ensures that the products meet market requirements.

At Hengjiu, we conduct rigorous inspections at the raw material stage to ensure consistent product quality. We use advanced raw material inspection equipment to verify that each batch meets the highest standards, laying a solid foundation for producing superior products.

IQC Raw Material Inspection

-

Cross-cut test

Ensures that the paint adheres strongly to the carbon Aluminum surface, preventing peeling and flaking.

-

Yellowing Resistance Test

Assesses the material’s resistance to discoloration when exposed to UV light, maintaining the visual appeal over time.

-

Glow wire test

Evaluates the ignition hazard and fire resistance of materials under high-temperature conditions(650℃ or 750℃).

-

Needle flame test

Simulates a small flame ignition source to evaluate the fire resistance and durability of the materials.

-

Salt spray corrosion test

Detect the corrosion resistance of metal materials such as screws.

Production Team

Our product development team establishes stringent Standard Operating Procedures (SOP) to ensure the high quality and consistency of each product.

Hi-Pot, insulation resistance.

Grounding test

Hi-Pot

Power Test

IPQC (In-Process Quality Control)

Monitors the core known points of specified processes, ensuring that the production site follows the established development standards and SOPs. Issues are presented through IPQC reports.

-

First Article Inspection

FAI ensures quality, prevents defects, and confirms compliance pre-production.

-

Two-hourly inspections

Monitor equipment, quality, and safety to prevent defects, ensure compliance, and maintain production continuity.

-

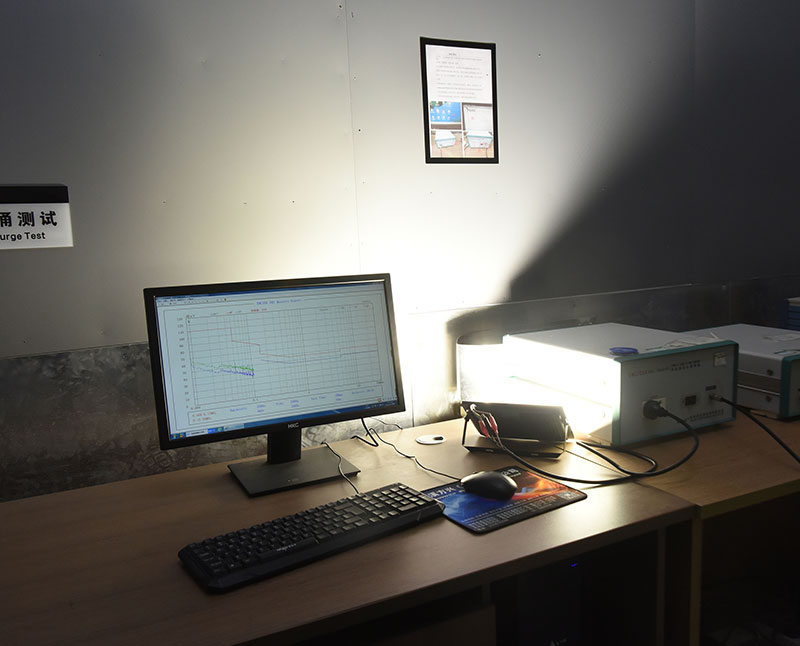

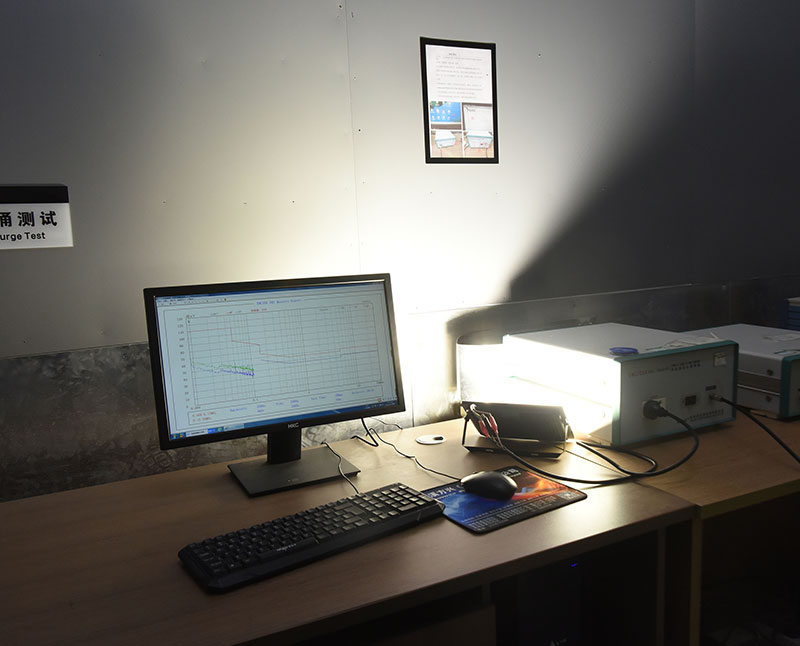

Batch aging

According to the product's performance, lifespan, and prior experience, the aging test is conducted in batches for 2 to 8 hours to ensure compliance with quality standards.

FQC(Final Quality Control)

Adopts customer FQC standards, transforming them into internal standards. For OEM products,Some customers establish specific standards based on unique application environments.

For instance, products intended for use in coastal areas must undergo a salt spray test lasting 500 hours.

NCR (Non-Conformance Report)

Despite rigorous controls, a small number of Non-Conformance Reports may still occur. Customer-provided NCRs are appreciated and utilized to continuously improve and optimize processes. Upon receiving customer feedback, standards and control points are synchronized with the production management system. Production follows SOPs, audits and IPQC conduct inspections based on control points, and finished products are inspected according to customer standards before being placed into inventory.

English

English Español

Español