Features

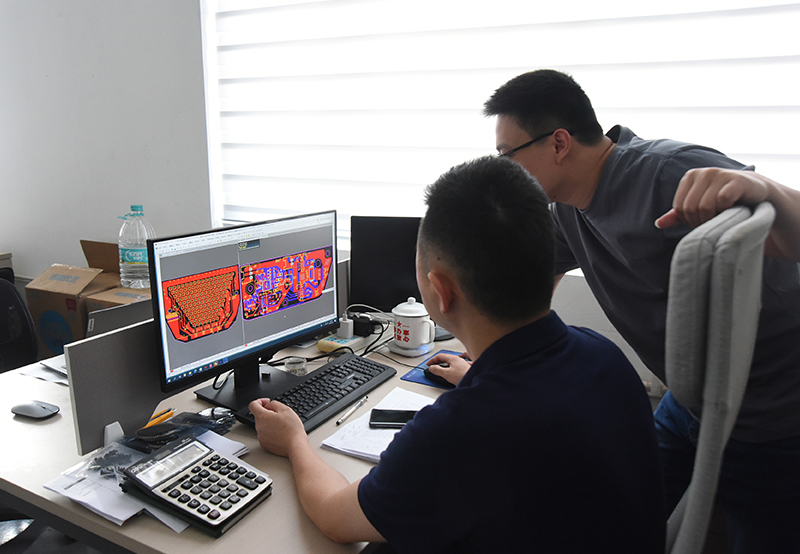

High-Density Component Integration

Miniaturized PCB design for compact and lightweight luminaires.

Advanced SMT (Surface Mount Technology) to integrate LED drivers, sensors, and control modules within limited space.

Customized IC solutions tailored for dimming, color tuning.

Signal Integrity & EMI Control

Multi-layer PCB layout with dedicated ground/power planes to minimize electromagnetic interference (EMI).

Shielding and filtering techniques to comply with international EMC standards (e.g., CE).

Optimized trace routing to reduce signal loss and heat generation.

Thermal Management System

Heat dissipation simulation using CFD tools to optimize component placement.

Thermal vias and heat sinks integrated into PCB design for efficient heat transfer.

High-temperature-resistant materials (e.g., FR-4 with Tg≥170°C) to ensure stability under prolonged operation.

Power Efficiency & Stability

Precision voltage regulation circuits to maintain stable output (±1% tolerance).

High-efficiency LED drivers (e.g., ≥90% efficiency) with PFC (Power Factor Correction) for energy-saving compliance.

Redundant circuit protection (over-voltage, short-circuit, surge) to enhance product lifespan.

Rigorous Validation Process

Environmental stress testing (thermal cycling, humidity, vibration) to simulate extreme conditions.

EMC pre-compliance testing to ensure global certification requirements.

Long-term aging tests (1000+ hours) for reliability validation.

Coming From China, Marketing To The World.

Coming From China, Marketing To The World.

English

English Español

Español